Ever wondered why your Glock 17, hailed as the most reliable handgun, suddenly jams or feels off? You’re not alone!

Many shooters have faced these hiccups, turning their smooth shooting experience into a bumpy ride. But what exactly goes wrong? And more importantly, how can you fix it?

Stay with us as we delve into the common problems of the Glock 17 and unveil some simple, yet effective solutions. Ready to turn your Glock 17 issues from ‘why me?’ to ‘solved’?

Problems and Solutions Table

| Problem | Solution |

| Ejection Issues | Rack slide forcefully, simulate ejector operations |

| MOS System Glitches | Use a caliper for level, consider a milled slide |

| Magazine Jamming | Opt for magazines with stronger springs (“2” next to logo) |

| Trigger Sticking | Clean and lubricate, adjust connector, replace firing spring if necessary |

| RSA/Guide Rod Misalignments | Ensure proper seating of components |

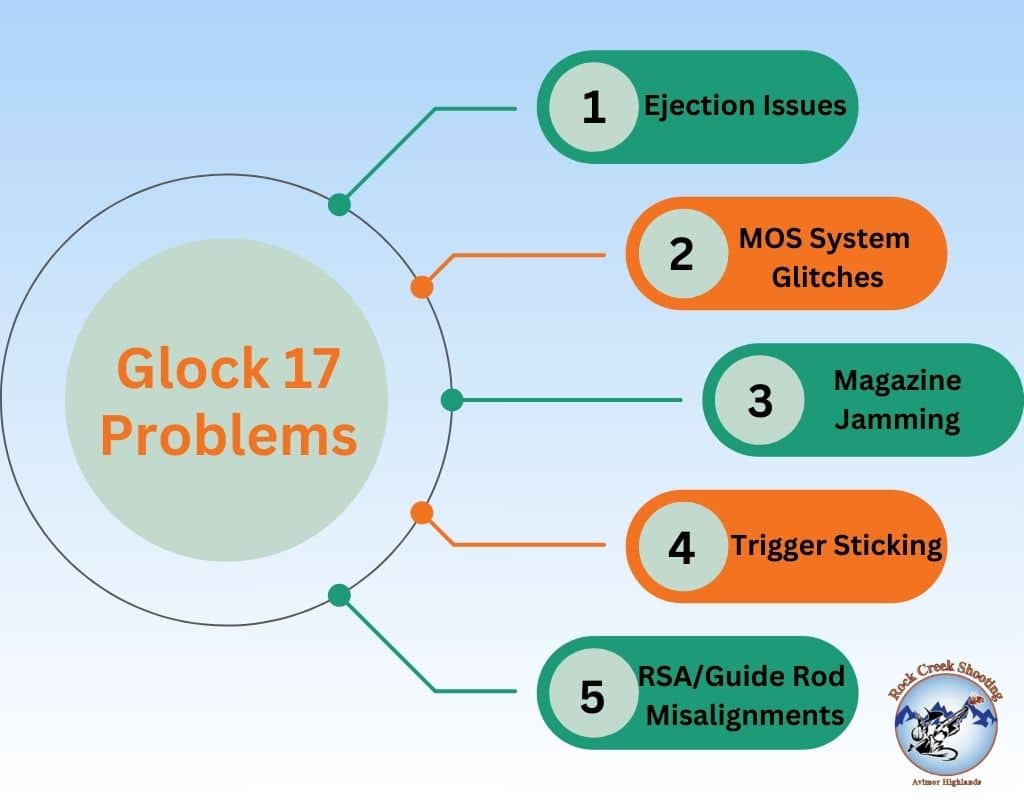

5 Common Glock 17 problems and Solutions

Ejection Issues

Sometimes, Glock 17 users experience a failure in the ejection process, where the firearm refuses to eject a spent casing or a live round. This malfunction can interrupt the shooting process, requiring manual intervention to clear the obstruction.

The issue often arises due to insufficient force applied during the slide’s backward motion, which fails to mimic the natural speed and force exerted by the firearm’s internal mechanisms during shooting.

Solution

The recommended fix is to practice a more forceful racking of the slide. This method works because it better simulates the speed and force of the ejector and extractor mechanisms as they function during firing.

By manually replicating the natural dynamics of these parts, shooters can improve the reliability of the ejection process, reducing the likelihood of malfunctions.

MOS System Glitches

Problem Explained: The Modular Optic System (MOS) on the Glock 17 can sometimes present alignment issues, making it difficult for shooters to quickly and accurately locate the red dot sight above the bore.

This difficulty can impair aiming precision and speed, especially under stress or in dynamic shooting scenarios. The problem may stem from an uneven mounting surface or improper installation of the optic.

Solution

Addressing this issue involves ensuring that the MOS platform is perfectly level, which can be achieved using precision tools like calipers.

For those still facing difficulties, opting for a slide that has been specially milled to accommodate their specific optic can provide a more stable and aligned mounting solution.

This adjustment not only facilitates quicker sight acquisition but also enhances overall shooting accuracy.

Magazine Jamming

Glock 17 users sometimes report jamming issues, particularly with 10-round magazines.

This problem is often attributed to the use of springs that don’t provide sufficient force to reliably feed rounds into the chamber, leading to frequent and frustrating stoppages.

Solution

A practical solution is to identify and use magazines that incorporate stronger springs, which are typically marked with a “2” next to the Glock logo.

These springs offer improved tension and reliability, significantly reducing the incidence of jamming.

By selecting magazines with these upgraded springs, shooters can ensure smoother feeding and better performance from their Glock 17.

Trigger Sticking

Problem Explained: After extensive shooting sessions, approximately around the 300-shot mark, the Glock 17’s trigger may fail to reset properly.

This issue can result from the accumulation of debris and fouling inside the trigger mechanism or wear and tear on the firing spring.

Solution

Regular maintenance, including a thorough cleaning and lubrication of the firearm, can alleviate this problem.

Ensuring the trigger mechanism is clean and well-lubricated helps maintain smooth operation and reliable resetting.

If the issue persists, inspecting and potentially replacing the firing spring can restore proper trigger function.

RSA/Guide Rod Misalignments

The recoil spring assembly (RSA) and guide rod of the Glock 17 may occasionally become misaligned, especially during press checks or when reassembling the firearm after maintenance.

This misalignment can cause the guide rod to protrude incorrectly or even dislodge from its seating, affecting the firearm’s reliability and operation.

Solution

Careful reassembly and verification that the RSA and guide rod are correctly seated can prevent these issues.

Ensuring that these components are properly aligned and securely in place supports the smooth operation of the firearm, reducing the risk of malfunctions and improving overall reliability during use.

Maintenance Tips

Keeping your Glock 17 in top condition isn’t just about cleaning; it’s about understanding its needs.

Regular checks on the RSA and guide rod positioning, along with mindful magazine maintenance, can save the day.

Ever thought of keeping a log of your cleaning and maintenance schedule? It could be a game-changer.

FAQs

Is Glock 17 the most reliable handgun?

Absolutely, with proper maintenance, it stands as a beacon of reliability.

Why does my Glock 17 keep jamming?

Often, it boils down to magazine issues or the need for a good clean.

How can I improve my Glock 17’s performance?

Regular maintenance and addressing the common issues we’ve discussed can significantly enhance its performance.

Conclusion

So, we’ve tackled the daunting question: What is the problem with Glock 17? From ejection hiccups to trigger troubles, it seems every problem has a solution. Remember, even the most reliable handgun, like the Glock 17, needs a bit of TLC to keep it running smoothly.

With the tips and solutions we’ve shared, you’re well on your way to ensuring your Glock 17 remains a reliable companion on and off the range. Feel like we’ve had a good chat? We hope so! Here’s to trouble-free shooting ahead!